Koenigsegg Regera KNC

Supercars with bodyworks in bare carbon aren’t new. Already in the late 1990s, first manufacturers tried their luck on this elaborate method, in which not only the fibers on one component must be laid as evenly and cleanly as possible, but as a supreme discipline also the weave direction between the different components should fit each other in the end, so everything acts as if it came from the same mould. In addition to Dauer, Bugatti, Pagani, Lamborghini, Donkervoort, McLaren and the unofficial customization department of Ferrari and Maserati, Zanasi, also Koenigsegg built bare carbon production cars in the meantime. Other manufacturers such as Mercedes-Benz, BMW, Porsche, Lexus, Bentley and various others only showed bare carbon attachment parts or sometimes bigger body parts like bonnets or roofs in bare carbon.

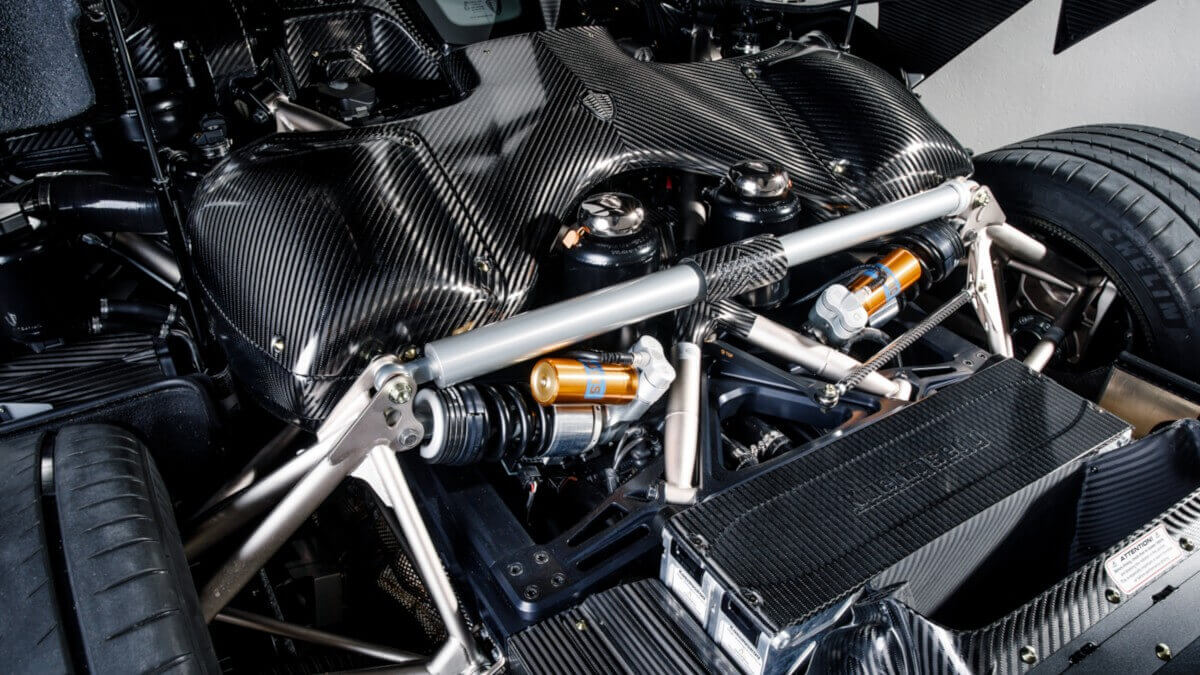

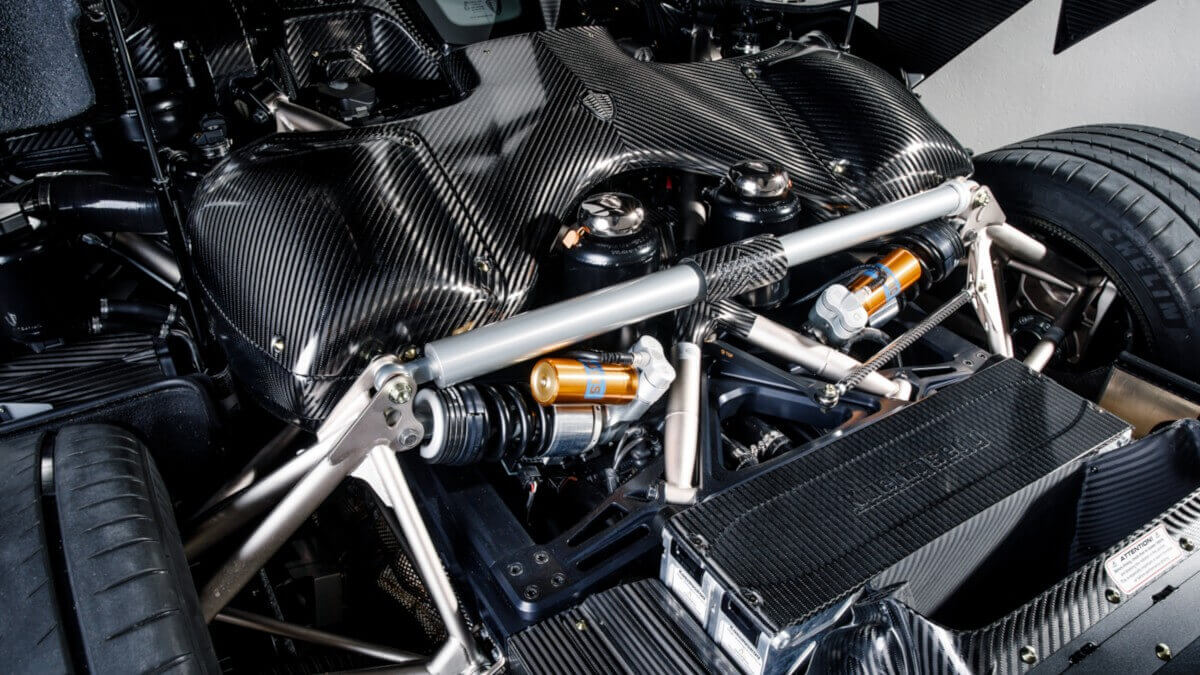

Next to the possibility of coating the parts with colored clear coats or dyeing the carbon fibers during production, there has only been the classic look of unpainted bare carbon with normal clear coat. Now Koenigsegg presents a new process, that is more complex than traditional methods, but also brings an interesting new look into the game. The ‘Koenigsegg Naked Carbon’ (KNC) uses neither color particels nor a clear coat. On the contrary, even the fine layer of epoxy adhesive, which normally covers the top of the components, is polished down by hand. While doing so, the respective employee has to be extremely cautious, since one stroke too many will ruin the weave structure of the carbon fibers. However, the result is breathtaking, since now the graphite layers of the carbon are clearly visible.

In recent years, Koenigsegg already tried and perfected the KNC method on their own Aircore carbon rims, wings, spoilers, winglets and steering wheels. In addition, some custom-made specimens were purposefully exposed to summer sunlight and cold weather in winter over several years to reveal any possible problems with the structures. In this time it became clear that KNC surfaces are significantly more resistant to scratches or stone chips than soft clearcoats. After these tests were successfully completed, it was now possible to build a full vehicle in KNC for the first time. For this, absolutely perfect moulds had to be created, since a correction of the shape by transparent paint filler or sanding is not possible.

The first KNC vehicle is a Koenigsegg Regera. This hybrid hypercar was shown for the first time at the Geneva Motor Show 2015 and is finally entering series production now. In total, only 80 copies of the 1,500-hp vehicle are produced by hand, all of which have already been pre-ordered. In contrast to conventional cars, the Regera has neither a manual or an automatic transmission, but a Direct Drive system to the rear axle. A total of three electric motors helps the biturbo V8 engine. One of which serves as a starting aid directly on the crankshaft while the other two provide additional power at the wheels. For the development of the batteries, Koenigsegg turned to the Croatian maker of electric sports cars, Rimac. Thanks to the deleted clear coat layers, the KNC Regera weighs about 20 kilograms less than a normal Regera. The vehicle was recently handed over to its new owner in Switzerland.

Images: Koenigsegg, Keno Zache